Description

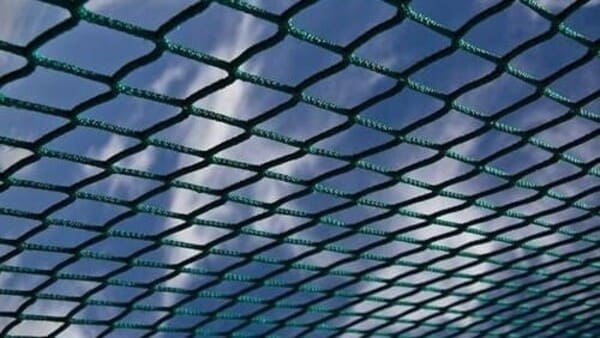

debris netting, is aslo called debris net, scaffolding net, scaffold netting, construction net, construction debris safety net.

It is installed vertically on the facade of construction building to protect the people or debris falling down.

It is made of HDPE, which is produced by knitted weaving machines. The process is same as shade net.

It is widely used in the construction site, such as buildings, bridges, etc.

Main Advantages

- Light weight - It is very light, so it is easy to handle and install.

- Durable - it is strong and longlasting, it can be used for several years because of the UV.

- Breathable - it is ventilative, so it will not be hot in the construction.

- Shading - it also can provide shade for the workers in the construction.

- Privacy - it can provide the privacy for the construction inside.

Types of debris netting

There are several types of debris netting, the difference is the structure. Here are several popular structures in the market. It also can be customized for you as your samples.

This is the most popular type in the market, the structure is same as the mono shade net.

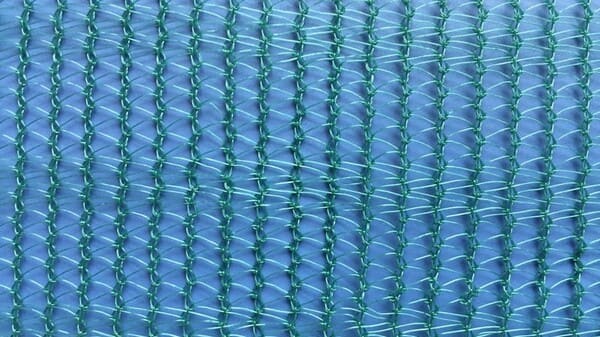

This is another popular type in the market, it is also could be used as bird net, olive net.

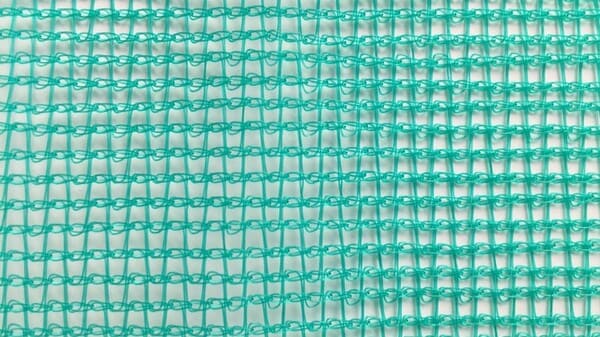

This structure is normal in safety net. It is popular in some markets.

Production of debris netting

The debris netting was produced by many steps, including the extrusion, weaving, rolling and packing.

Raw material

The raw material of debris netting is HDPE. To make the nets more durable, we will add the UV into the materials.

Extrusion

The thread will be extruded by the extrusion machines. All the debris nettings are produced by mono thread.

weaving

The mono threads will be woven into different struction by raschel knitted machines.

rolling

The debris netting will be divided into small roll of 50m or 100m by the rolling machines. it also could be folded during rolling.

packing

The debris netting each roll will be put into a plastic bag, and the labels will be put inside together.

shipping

The rolls of debris netting will be loaded into the container, which will be shipped to our clients around the world.

How to choose the debris netting

To make sure the debris netting will be accepted and hot sale in your market, there are several factors you should consider.

material

- HDPE - Nearly all the debris netting is made of HDPE. Some safety net is made of 100% virgin HDPE, some debris nettings are made of recycled HDPE.

- UV - To make the debris netting more durable, we could add the UV into the raw materials during extrusion.

- Color master - The debris netting could be customized in many colors, the quality of colors depends on the quality of color master.

- Flame-retardant - If some market, the debris netting need be flame-retardant. it can reduce the risk of fire.

High quality debris netting depend on high quality HDPE, UV, color master and other additives. Meanwhile, the cost would be also high.

weight

- Strength - Heavier debris netting has higher strength. If you want to protect the passby from the falling debris, 80-100g would be enough. If you want to prortect the people from falling, the weight would be over 150g.

- Durability - A heavier net is generally more durable and will last longer than a lighter net.

- Cost - The weight of debris netting is higher, the cost would also be higher.

Colors

- Preference - The people in different market has their own preference. the normal color in the market is red, blue, green, white, dark green, etc.

- High Visibility - it should be highly visible to prevent accidents. The color you choose should be bright and easily recognizable, so it can be seen from a distance.

- Production - All the colors would be customized for you. If you have special requirements in color, you should send the sample to us to analysis.

Other details

To help fastent the debris netting on the scaffold, the edges could be woven with eyelets.

The debris netting could be woven in 2 or more colors for you. Many details could be customized.

As usual, it could be folded and packed by roll, the rolls will be put into a plastic bag.

How to buy debris netting

If you want to find a suitable supplier, here are some steps for your reference.

Specifications discuss

You could have a talk with your supplier about their products and factory.

Quotation

in the further talk, you could share the specifications with them, and ask for a best price.

Samples check

To check the quality, you could ask the suppliers for the samples to check their quality. You also could check the photos and videos of their production.

Order comfirm

After comparing the price and quality, you would have a discuss with your management, and decide to choose the best supplier.

Production

The supplier will start to produce the debris netting as your requirement. You could ask the photos and videos of the production several weeks later.

shipping

All the goods will be loaded into the container when it is prepared. As usual, the supplier will share the photos or videos of loading with you.

Let's talk now!