Description

With the development of technology, FISH CAGE became more and more popular in the last decade. Compare to the steel fish cage, the HDPE fish cage is easy to be shipped to everywhere.

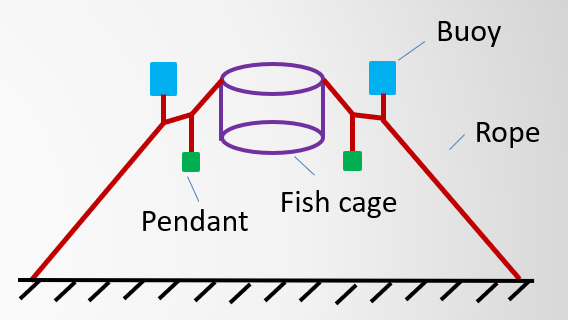

To meet the requirements of the fish cages in the sea, our deep sea fish cage has special design in structure, mooring systerm and netting to reduce the impact in the harsh weather.

Parts of fish cage

The structure is made of 100% HDPE, the floating pipe is designed as 8 Individual cabins. Even half of the cabins are broken, the fish cage won’t sink.

This kind of mooring systerm is designed specially for the deep sea fish cage, it can minimize the impact of wind and waves on the fish cage.

There are usually 2 layers of cage net. They will be installed in our individual workshop. The nets will be sewed piece by piece with rope by hand.

Experienced Team

Besides the cage netting, we can work with our partners in China to prepare the completed proposal for our clients around the world. If you want more details, contact us now!

Production of HDPE structure

The structure of fish cage is made from many different parts, the main parts include floating pipe, bracket, handrail pipe, fence railing, etc.

Raw material

Our raw material is imported from Borouge in UAE, the service life of the pipe can reach more than 15 years.

Pipe Extrusion

All the pipes are extruded by production lines , which are imported from Battenfeld and Krauss Maffei.

Parts extrusion

All the parts are produced in our individual workshop, each part has their special model. All the extrusion machines are controlled by computer.

Production of rope and netting

All the fish cages will be installed in our individual workshop. The nets will be sewed piece by piece with rope by hand. We will improve the process year after year to increase the service life of fish cage.

Net weaving

The nets would be produced by our weaving machines by pieces. The cage net is usually made from knotless net.

Rope making

The ropes will be produced by our rope making machines by rolls. The normal material is PE and PP, we also have other options to choose.

Nets Sewing

The cage nets are sewed by nets piece by piece with ropes by hand. If there is 2 layers, the inner net and outer net also need be sewed together.

Test in the lab

All the HDPE parts need have a test in the lab each batch. And the result should be approved before shipping.

Ageing Test

The HDPE products will be used outside all the time, so the anti-ageing property is very important. We need test the raw materials in the lab before production.

Sample Making

We need test many different kinds of properties for the HDPE pipe. Before that, the samples should be made in standard size.

Property Test

There are many propertities need be test before shipping, including the breaking strength, impact strength, etc.

Our Projects

We have many fish cage projects since 2015, most of them is located in the sea. All of them worked well after several typhoons every year.

180 cages in Hainan

It was finished in 2015, it is located in the sea, the depth of sea is 10-30m. The fish in the farm is pomfret, the annual capacity is 8,000tons.

200 cages in Fujian

It was finished in 2018, it is located in the sea, the depth of sea is about 10-30m. The farming fish is yellowtail, the annual capacity is over 5,000tons.

10 cages in Guangxi

It was finished in 2020, it is located in the sea, the depth of sea is about 30m. The fish in the farm is pomfret, the annual capacity is 8,00tons.

6 steps of fish cage projects

The fish cage projects is a multi-sector works, including the engineering, purchasing, quality, finance, goverment, production, logistic, shipping team, etc.

Proposal Design

The proposal includes cage diameter, height, quanity, project location data, drawing of fish cage, material list, price, shipping details, etc.

Budget approved

The total cost should be calculated, including the material price, shipping cost, clearance fees, transportation cost, installation cost, operation cost, etc.

goverment approved

Each project should be approved by the location goverment, all the activities should meet the requirements of environment, health, safety, tax and other policy.

Production

The production will be started when the project is confirmed, the order should include the material list, price, quantity, delivery time and payment term.

Shipping

To reduce the shipping cost, there would be a shipping proposal, including the material list, quanity for each container.

Installation

There will be a guide to introduce all the details in the installation. And we will have a project manager to give the technical support on the installation site.

Let's talk now!