Safety is the most important thing in the construction site. However, construction sites are dynamic environments where countless workers engage in tasks that involve significant risks.

To mitigate these risks and prioritize worker safety, various safety measures and equipment are deployed. Among the essential tools employed in the construction industry, safety nets play a pivotal role.

What Is The Safety Net

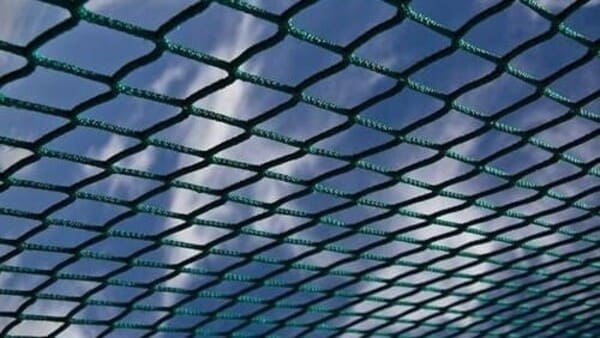

Safety net is one kind of net used as a barrier or catchment system to arrest the fall of a person or objects, minimizing the potential impact and reducing the risk of severe accidents. It is used to prevent falls and protect workers from injuries or fatalities.

Safety nets in construction serve as a vital safeguard against falls from heights. Construction sites often involve work at elevated levels, such as scaffolding, roofs, or upper floors of buildings, making falls a significant hazard.

Safety nets are specifically designed to arrest a fall and prevent workers from hitting the ground, reducing the risk of severe injuries or fatalities.

It acts as a reliable backup system in case other fall protection measures, such as harnesses and guardrails, fail. It is the last protection for workers, so it is very important in the construction site.

How It Works

Safety nets are constructed using high-strength synthetic materials, typically polypropylene, with a mesh-like design.

They are strategically positioned below elevated work areas to catch falling workers or objects. When a fall occurs, the safety net absorbs the impact energy, distributing the force across the net and minimizing the risk of injury.

The flexibility and strength of the netting material ensure that it can withstand the impact and prevent workers from hitting the ground or lower levels of the construction site.

Why Choose Safety Net

There are many solutions for safety in construction, but why more and more people choose the safety net? I would like to share some benefits of safety net with you:

Fall Protection

The primary benefit of safety nets is their capability to protect workers from falls.

By creating a reliable barrier between workers and the ground, safety nets significantly reduce the risk of severe injuries or fatalities caused by falls from heights.

Confidence And Productivity

Knowing that safety nets are in place instills confidence in workers, allowing them to focus on their tasks without constant worry about their safety.

This, in turn, enhances productivity and contributes to a positive work environment. It can improve the enthusiasm and efficiency of workers.

Cost Savings

While the initial investment in safety nets may be incurred, they can lead to long-term cost savings.

By preventing injuries and accidents, safety nets help construction companies avoid medical expenses, worker compensation claims, legal battles, project delays, and reputational damage.

Versatility

Safety nets can be tailored to fit various construction site requirements.

They are adaptable to different shapes, sizes, and configurations, allowing their effective use in a wide range of construction projects, including high-rise buildings, bridges, and industrial structures.

The service time of safety net with UV could be 3-5years or more. this is also could reduce the cost of materials.

Types Of Safety Net

There are several types of safety nets designed for different applications and purposes. In construction site, there are 2 types of safety net: debris netting and anti-fall net. General speaking, The former is installed in vertical way, and the latter is installed in horizontal way.

Debris netting

Debris netting, also known as debris safety netting or scaffolding net, is a type of protective barrier used to contain and prevent the spread of debris in various settings.

It is commonly utilized in construction sites, demolition projects, and other situations where there is a risk of loose objects or materials falling and causing damage or injury.

Debris safety netting is typically made of high-strength, durable materials such as polyethylene. It is constructed with small mesh openings that allow air to pass through while effectively trapping and containing debris.

The netting is designed to withstand the impact of falling objects and is installed vertically or horizontally, depending on the specific application.

The primary purpose of debris safety netting is to create a physical barrier that prevents debris from falling beyond a designated area.

It helps protect workers, pedestrians, and nearby structures by containing loose materials such as rocks, tools, construction waste, or other objects that may pose a hazard. In addition to safety, debris netting also aids in maintaining a clean and organized work environment.

Debris safety netting is typically installed along the perimeter of elevated work areas, scaffolding, or construction sites where there is a risk of debris falling.

It can also be used to enclose scaffolding to prevent objects from being accidentally knocked off. Proper installation and regular inspections are important to ensure the netting’s integrity and effectiveness in containing debris.

While anti-fall safety netting is designed to catch and protect individuals from falls, debris safety netting focuses on preventing loose objects or debris from causing damage or injury to people or property.

Anti-fall net

The anti-fall safety net is a protective device used to prevent or minimize injuries caused by falls from heights. It is commonly employed in construction sites, industrial settings, and other work environments where there is a risk of falling.

It is typically made of strong, durable materials such as nylon, polyester or polyethylene and is designed to withstand the impact of a falling person.

It is installed horizontally below the work area, spanning the distance where falls are likely to occur. The netting is secured to an adequately strong supporting structure, such as scaffolding or steel beams, to ensure its stability.

The primary function of an anti-fall safety net is to catch and absorb the energy of a falling person, preventing them from hitting the ground or lower-level surfaces. It acts as a passive safety measure, reducing the risk of severe injuries or fatalities.

Safety nets are often used in conjunction with other fall protection systems, such as harnesses, guardrails, or personal fall arrest systems, to provide comprehensive protection against falls.

By installing anti-fall safety nets, employers and workers can create a safer working environment and comply with occupational health and safety regulations.

Regular inspections, maintenance, and proper training in fall prevention techniques are essential to ensure the effectiveness of the safety net system.

How to install the safety net

The installation of vertical and horizontal safety net is a little different. The vertical safety net is installed with the scaffolds. And the horizontal safety net should be installed on the special support structure, such as steel beam.

Installing a vertical safety net typically involves the following steps:

- Assess the work area: Determine the specific areas where the vertical safety net needs to be installed based on the potential fall hazards. Consider the height, dimensions, and layout of the work area.

- Select the appropriate safety net: Choose a vertical safety net that is suitable for the intended purpose, taking into account factors such as net size, strength, and load capacity. Ensure that the net meets relevant safety standards and regulations.

- Prepare the supporting structure: Identify the anchor points or structures where the safety net will be attached. This could be scaffolding, building columns, or other secure points capable of withstanding the forces exerted on the net during a fall.

- Measure and cut the net: Measure the height and width of the area where the safety net will be installed. Cut the net to the appropriate size, leaving some extra length for attaching and securing it to the anchor points.

- Attach the net to the anchor points: Start at one end of the safety net and secure it to the first anchor point using appropriate fasteners or hooks. Gradually work your way along the net, attaching it securely to each anchor point. Ensure that the net is evenly spread and taut.

- Secure the edges: Secure the edges of the net to the supporting structure or anchor points using additional ropes, cables, or fasteners. This will prevent the net from being dislodged or coming loose.

- Test the installation: Once the safety net is installed, conduct a thorough inspection to ensure it is securely in place and properly tensioned. Apply appropriate force to test the net’s stability and ensure it can withstand the impact of a fall.

- Regular inspections and maintenance: Regularly inspect the safety net to check for any signs of wear, damage, or deterioration. Replace or repair any damaged components promptly to maintain the net’s effectiveness.

How to choose the safety net

There are many kinds of nets could be used as safety net in the market. It includes HDPE raschel knitted nets, HDPE twisted net, HDPE knotless net, HDPE braided net, etc.

The HDPE raschel knitted net is usually used as debris netting, it could be installed as the facade of the building. it could provide the protection and shade for the workers, and it is ventilated. it is very cool in the hot season. The normal weight is about 60-100gsm.

Meanwhile, it is also could be used as anti-fall net. it should be strong enough to withstand the impact of the person. So the weight would be heavier than debris netting, should be about 150g at least.

The HDPE knotless net is usually used as anti-fall net. it is smooth on the surface, so it is friendly to the person. To withstand the impact of falling, the twine would be thick enough, and the mesh size could be bigger than debris net, the mesh size would be 25-50mm.

The HDPE twisted net and braided net are usually used as anti-fall net. but it should be used with debris net together as double layers. the twisted net or braided net would be installed on the bottom, and the debris net is installed on the top.

Conclusion

There are 2 main types of safety net: debris netting and anti-fall net.

The debris netting is used to prevent the debris from causing damage or injury to people. And the anti-fall net is designed to catch and protect the people from falls, it is the last safety measure in construction.

If you’ve read this far, I think you might be clear about the safety nets in construction. If you still have any questions or other opinions, I will be appreciate to hear from you.