Description

Shade net, also known as shade cloth, is a woven or knitted fabric made from HDPE.

It is typically used for providing shade and protection from the sun’s harmful UV rays in outdoor areas such as gardens, patios, and agricultural fields.

it comes in various shade rate, ranging from 20% to 98%, which determines the amount of sunlight that can pass through the fabric.

Popular Applications

- Agriculture - is extensively used in agriculture for crop protection from excessive sunlight, heat, and wind.

- Greenhouse - is widely used in greenhouse as a covering to control the amount of sunlight in the greenhouse

- Livestock - used to provide shade and shelter to livestock, including cattle, horses, and other animals.

- Garden - is also used in residential settings, such as patios, decks, and gardens

- Park - is used in outdoor recreational spaces, including parks, playgrounds, and sports fields.

- Construction - is used as safety net in construction sites to provide shade to workers and protect them from falling.

Types of shade net

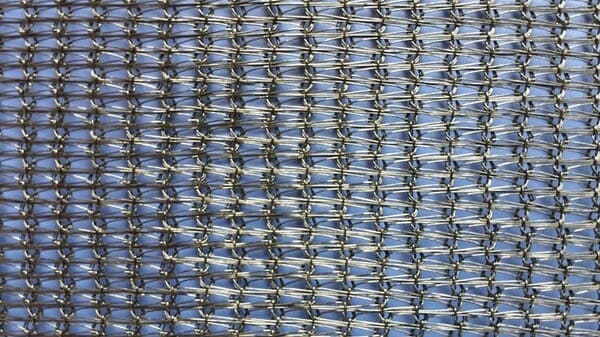

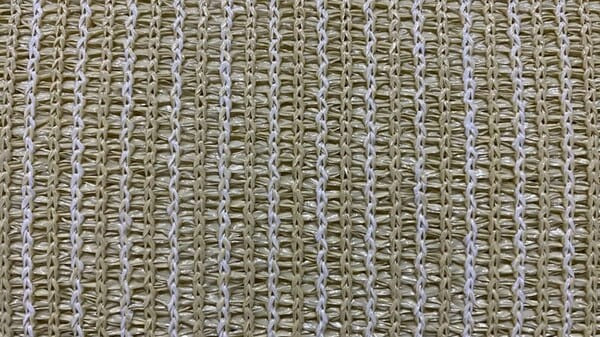

According to the process of production, the shade net could be classified into knitted shade net and woven shade net.

It is produced by raschel knitted machines. It is lightweight, durable, and provides good ventilation. This is the most popular struction in the market.

It is produces by Sulzer Rutti Loom. Compared to knitted shade net, it is heavier, more durable, and provides better protection against wind.

Types of shade net

According to the thread of shade net, it could be classified into tape shade net, mono shade net and tape x mono shade net.

The warp and weft of tape shade net are all woven by tape thread. it has high shade rate with light weight.

The warp and weft of mono shade net are all woven by mono thread. Compared to tape shade net, it has higher strength, and heavier weight with same shade rate.

The warp of shade net is tape and the weft is mono, it has better strength than tape shade net, and lighter weight than mono shade net with same shade rate.

Production of shade net

The shade net was produced by many steps, including the extrusion, weaving, rolling and packing.

Raw material

The raw material of shade net is HDPE. To make the nets more durable, we will add the UV into the materials.

Extrusion

The thread will be extruded by the extrusion machines. The mono and tape thread will be produced by different dies.

weaving

The threads will be woven into different struction by raschel knitted machines or woven machines.

rolling

The shade net will be divided into small roll of 50m or 100m by the rolling machines. it also could be folded during rolling.

packing

The shade net each roll will be put into a plastic bag, and the labels will be put inside together.

shipping

The rolls of shade net will be loaded into the container, which will be shipped to our clients around the world.

How to choose the nets

To make sure the shade net will be accepted and hot sale in your market, there are several factors you should consider.

Material

- HDPE - Nearly all the shade net is made of HDPE. Some shade net is made of 100% virgin HDPE, and some shade net is made of recycled HDPE.

- UV - To make the shade net more durable, we could add the UV into the raw materials during extrusion.

- Color master - The shade net could be customized in many colors, the quality of colors depends on the quality of color master.

- Flame-retardant - we also could add the fire retardant into the raw material to make the shade net be flame-retardant.

shade rate

- Crops - Some crops require more shade than others. For example, leafy greens like lettuce and spinach require more shade than fruits like tomatoes and peppers.

- Stage of Growth - Some crops require more shade during certain stages of growth. For example, seedlings may need more shade than mature plants.

- Weather Conditions - In hot and dry weather, crops may need more shade to protect them from excessive heat and sunlight. In cooler weather, crops may need less shade to allow for more sunlight to reach them.

weight

- Shade Rate - The weight of the net is generally proportional to the shade rate. So, if you need a higher shade rate, you need a heavier net.

- Strength - Heavier shade net has higher strength, it can make the shade net withstand wind, hail or other bad weather.

- Durability - A heavier net is generally more durable and will last longer than a lighter net.

- Cost - The shade net is higher, the cost would also be higher.

General speaking, 30-120g shade net is usually used in agriculture and greenhouse. 80-150g is usually used in livestock and construction, 150-300g is usually used in garden and park.

Colors

- Crops - The normal colors for crops are black, white and green. some special crops prefer special colors, such as red, blue, etc.

- Livestock - the shade net for livestock is usually black or dark color to provide more shade.

- People - the colors of shade net for poeple will be various to meet the various preference of people in different culture, age, gender, etc.

The people has their own preference in different market, some colors would be hot sale, and some not.

Packing

the normal packing method is packing by roll. The shade net is packed by roll, and put it into a plastic bag with the label inside.

the shade net in small size, such as 1x20m, 2x10m, need be packed piece. it will be folded by hand and be put into a plastic bag and CTN. This shade net is usually sold in online store.

some shade net will be sold in supermarket or online store, it need be packed by CTN, which will help them be sent by express easily.

Other details

There are several different kinds of eyelets to choose. it is used to fasten the shade net.

The edge of shade net could be woven in different color. Different colors represent different weight or shade rate to identify.

There are many different accessories to fasten or connect the shade net.

How to buy shade net

If you want to find a suitable supplier, here are some steps for your reference.

Specifications discuss

You could have a talk with your supplier about their products and factory.

Quotation

in the further talk, you could share the specifications with them, and ask for a best price.

Samples check

To check the quality, you could ask the suppliers for the samples to check their quality. You also could check the photos and videos of their production.

Order comfirm

After comparing the price and quality, you would have a discuss with your management, and decide to choose the best supplier.

Production

The supplier will start to produce the shade net as your requirement. You could ask the photos and videos of the production several weeks later.

shipping

All the goods will be loaded into the container when it is prepared. As usual, the supplier will share the photos or videos of loading with you.

Let's talk now!